Nowadays, ventilation engineering cannot be effective if it does not resort to specific analytical calculation programs.

In the real-world, it is very common to find oversized fans operating under conditions of poor performance, resulting in excessive and unnecessary consumption of electrical energy.

Our industrial fan software ensures accurate sizing of centrifugal fans, blowers and axial fans, harmonizing advanced techniques with the art of optimal selection.

Designed to meet the needs of the air moving industry, including HVAC, our industrial fan software is a dynamic tool that accurately performs sizing of centrifugal fans and blowers, and axial fans.

For the sizing of fans, the programming logic is developed according to engineering concepts homologated by international standards and institutions, such as:

The correlation functions used to calculate dimensional and physical parameters of each new fan have their origin in the classical theories of fluid mechanics, becoming known as the Fan Laws or Affinity Laws, while the noise predictions are based on acoustic principles and guidelines established by professional organizations.

For better accuracy, the software can also perform calculations and analysis improved by considering Reynolds number, Mach number, compressibility, viscosity and specific heat of the fluid.

In a highly organized, flexible and friendly environment, the user establishes the design requirements and the software performs all calculations and analysis necessary for sizing of the fan:

In addition to the aerodynamic requirements, the user can also set the fan installation conditions.

Installation factors significantly influence the sound spectrum of the ventilation system and consequently the level of noise sensed in the environment.

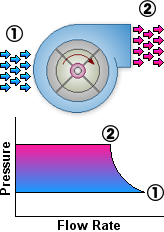

Usually, industrial fans are tested using ambient air; and their performance curves are published by manufacturers, conventionally referring to the standard parameters of this fluid at sea level.

In practice, however, most fans use air under adverse conditions, or even another type of fluid, and especially at altitudes other than sea level:

Obviously, the physical properties of these fluids are different:

Our software calculates the influence of these variants, adjusts parameters of the fans, and corrects their characteristic curves.

Thus, charts are displayed in a fully correct way, under the actual conditions of the user's application.

In ventilation systems, compressibility is the property of the moving fluid that reduces its volume as a function of the pressure increase resulting from the action of the fan.

Compressibility increases the density of the fluid.

The compression process generates heat which raises the outlet temperature of the fluid and consequently changes its viscosity.

All these variables modify the behavior and efficiency of the fan.

Our industrial fan software has advanced features that calculate and evaluate the influence of compressibility on fan sizing.

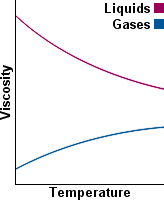

Viscosity is the physical property that characterizes the resistance of a fluid to flow.

It represents the internal friction of a moving fluid.

Unlike liquids, the viscosity of gases increases with increasing temperature.

The viscosity of the gases also increases with increasing pressure, but much less significantly.

The increase in viscosity implies an increase in the energy required to make the fluid flow and consequently changes the performance of the fan.

Our industrial fan software has advanced features that calculate and evaluate the influence of viscosity on fan sizing.

In fluid mechanics applied to ventilation systems, the Reynolds number can be defined as the ratio of the inertial forces to the viscous forces within the fluid moved by the fan.

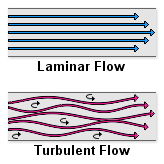

The Reynolds number makes it possible to predict whether a flow will occur in laminar or turbulent form.

If the viscous forces are dominant, the flow tends to be laminar.

If the inertial forces are dominant, the flow tends to be turbulent.

Laminar flow is characterized by smooth and constant motion of the fluid.

Turbulent flow is characterized by agitated and chaotic motion of the fluid, with eddies, vortices, backflows and other instabilities.

Therefore, the flow type changes the performance of the fan and consequently its energy consumption and efficiency.

Our industrial fan software has advanced features that calculate and evaluate the influence of Reynolds number on fan sizing.

Our industrial fan software is also prepared to meet the latest American requirements for fan efficiency classification.

The FEG classification system can be used by government agencies or regulatory bodies around the world to define the energy efficiency requirements of fans used in specific applications.

The FEG is a simple way to indicate the aerodynamic quality of the fan.

While the fan efficiency is a function of the operating point on the performance curve, the FEG is based only on the fan's peak total efficiency.

Similarly, our software also meets efficiency requirements of the European countries that prefer the FMEG classification system - Fan Motor Efficiency Grade.

Normative References:

In 2018, AMCA published a new standard establishing the method of calculating the FEI (Fan Energy Index).

FEI is the ratio of the electrical input power of a reference fan to the electrical input power of the actual fan.

FEI can be calculated for each point on a fan curve.

In contrast to the previous metrics, the FEI takes into account the efficiency of the electric motor as well as the transmission system.

Normative References:

In ventilation systems with variable demand, the use of adjustable speed drives is usually the best way to ensure maximum efficiency and minimum energy consumption.

Under such circumstances, it is essential that the designer has a broad view of the behavior of the fan to be selected.

Our software has the most advanced engineering charts with high resolution details, which show characteristic curves throughout the operating speed range of the fans.

Since fans and blowers are often driven by industrial electric motors, the software has an extensive database containing data of electric motors from around the world.

In addition to the operating conditions, the software allows the user to set up construction features and choose components for each fan, such as:

Once the fan has been selected, the software automatically generates all the engineering reports, datasheets, charts and CAD drawings in several standard paper sizes.

The display and printing of reports use a WYSIWYG (What You See Is What You Get) interface:

All of these documents can be easily customized, printed, emailed or exported to formats like:

As a result of customer demand for more flexible and comprehensive solutions, the software has a host of configuration options that allow the user to customize it to suit his personal wishes and preferences.

Built with multilingual user interface and an advanced unit converter, our software is fully capable to meet the needs and requirements of any manufacturer in the world, regardless of the volume of its production or the variety of its product range.

This software is intended exclusively for fan manufacturers, so there is not a version available to individual users.

We make a customized version for each client.

The general guidelines for the implementation of this software are described in the purchasing process of our software solutions.

If you wish to start the purchasing process or request more information about our industrial fan software, please contact us. We are able to develop a customized and exclusive version for your company.

Ciclo is a technology company that develops software for the design of machines. We take pride in providing top-notch solutions that strengthen our clients' businesses.

Copyright © 1998-2025 Ciclo Software Ltd. All rights reserved.